Die Casting Process

- Home

- Die Casting Process

|

Mould | Design → Making → Pilot Testing → Approval → Production. |

|

Die Casting | Ingot → Oven Melting → Injection → Cooling → Forming → Releasing → Trimming → Punching → Inspection. |

|

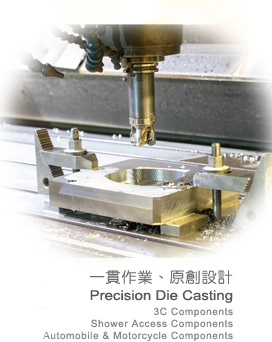

Finishing | Surface Calibration → CNC Machining → Other Finishing → Inspection. |

|

Grinding and Polishing | Precision Grinding by Swiss Made Robotic Grinding Machine or Manual Grinding or Vibration Grinding. |

|

Electric Plating | Inspection → Hook Hanging → Cold Rinsing → Ultrasonic Cleaning Washing → Primary Copper Plating → Washing → Secondary → Copper Plating → Washing → Third Nickel Plating → Washing → Color Finishing (Brass, Bronze, Nickel, Black Nickel, Chrome, Gold…etc.)→ Washing→Drying → Spraying → Drying→Inspection & Packaging. |

|

Coating | Degreasing → Ultrasonic Cleaning → Washing → Pickling → Washing → Drying → Spraying → Drying → Inspection & Packaging. |

|

Assembly | Components Assembly on Request. |

|

Final Inspection | |

|

Packaging | |

|

Warehous-ing |

Zinc Alloy Ingots for Die Casting

The high strength of the zinc alloy and its hardness characteristic make it become ideal substitute for aluminum to have higher ability of machining, suppressing, pressing and assembling. The zinc alloy shows outstanding ability of shock attenuation and vibration absorbability. In general, the tooling life of zinc alloy is at least 10 times longer than aluminum die cast tooling, in addition, the tooling expenses is also cheaper

Characteristic of the aluminum alloy:

- High strength and hardness

- High-accuracy dimension and stability

- The good filled ability of product's thin wall

- Remarkable corrosion resistance

- Excellent characteristic of electroplating

- Excellent electric conductivity

- High thermal conductance

- High repaired characteristic

- Abundant recycling

| Aolly | Al | Mg | Cu | Fe | Pb | Cd | Sn | Zn |

|---|---|---|---|---|---|---|---|---|

| Aolly3 | 3.5~4.3 | 0.02~0.05 | 0.25max | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| Aolly7 | 3.5~4.3 | 0.005~0.02 | 0.25max | 0.075 | 0.001 | 0.002 | 0.003 | Bal. |

| Aolly9 | 3.5~4.3 | 0.03~0.05 | 0.75~1.2 | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| Aolly2 | 3.5~4.3 | 0.02~0.05 | 2.5~3.0 | 0.1 | 0.003 | 0.004 | 0.005 | Bal. |

| ZA-8 | 8.0~8.8 | 0.015~0.03 | 0.9~1.3 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

| ZA-12 | 10.5~11.5 | 0.015~0.03 | 0.5~1.2 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

| ZA-27 | 25.0~28.0 | 0.01~0.02 | 2.0~2.5 | 0.075 | 0.003 | 0.006 | 0.006 | Bal. |

Application of Zinc Alloy Ingots

- (1) Electronic parts and Telecommunication equipment

- (2) Optical instruments and General instruments

- (3) Automobile and motorcycle parts

- (4) Commercial apparatus

- (5) House wares

- (6) Industrial apparatus

- (7) General hardware and Tools

Aluminum Alloy Ingots for Die Casting

In numerous casting alloys, the aluminum casting part is light and has better ability to endure the higher temperature condition to operate. The aluminum die casting not only has higher intensity and rigidity, but shows the premium ability of corrosion resistance and thermolysis (Spread heat), therefore, it is the ideal products which used in the all kind of harsh environment. In general, the tooling life of aluminum alloy is much shorter than zinc die cast tooling, in addition, the tooling expenses is also higher.

Characteristic of the aluminum alloy:

- Good ability to operate in high temperature environment

- Remarkable corrosion resistance

- High strength and hardness

- Light weight

- Good rigidity and intensity

- Excellent electromagnetic wave covered performance

- Outstanding thermolysis (spread heat)

- High conductive performance

- High repaired characteristic

- Abundant recycling

| 品名 | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Pb | Sn | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ADC3 | 9.0~10.0 | 0.9 | 0.6 | 0.3 | 0.4~0.6 | - | 0.5 | 0.5 | - | - | 0.1 | Bal. |

| ADC5 | 0.3 | 1.1 | 0.2 | 0.3 | 4.1~8.5 | - | 0.1 | 0.1 | - | - | 0.1 | Bal. |

| ADC6 | 1.0 | 0.6 | 0.1 | 0.4~0.6 | 2.6~4.0 | - | 0.1 | 0.4 | - | - | 0.1 | Bal. |

| ADC310 | 7.5~9.5 | 0.9 | 2.0~4.0 | 0.5 | 0.3 | - | 0.5 | 1.0 | - | - | 0.3 | Bal. |

| ADC12 | 9.6~12.0 | 0.9 | 1.5~3.5 | 0.5 | 0.3 | - | 0.5 | 1.0 | - | - | 0.3 | Bal. |

| ADC1 | 11.0~13.0 | 0.9 | 1.0 | 0.3 | 0.3 | - | 0.5 | 0.5 | - | - | 0.1 | Bal. |

Application of Aluminum Alloy Ingots

- (1) Electronic and Electric

- (2) Mechanical facilities

- (3) Transportation

- (4) Military industry

- (5) Architecture

- (6) Family products